Wuli Industrial District

Quanzhou City Fujian Province, China

+86-135-0505-2529

kathy@xdknitmachinery.com

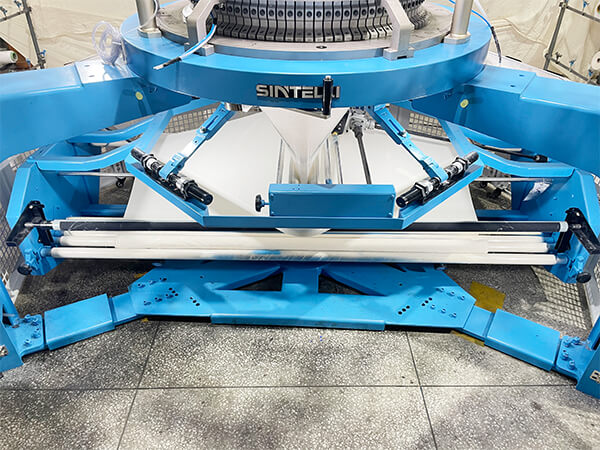

The cloth-cutting machine is equipped with a roller speed adjustment device that guarantees a uniform and stable knitting tightness to the fabric.

Guarantee a uniform and stable knitting tightness of fabric, crease-free and reduce wastage

Premium parts made by advanced CNC and quality central system, improved precision, easy to operate.Time-saving and efficient

The Open Width Circular knitting machine is fabricated based on the single jersey tubular knitting machine which enables the fabric to completely result in a crease-free, smooth texture. Fabric density, size and thickness can be easily adjusted with this type of configuration and thus can prolong the life of the needles and equipment.

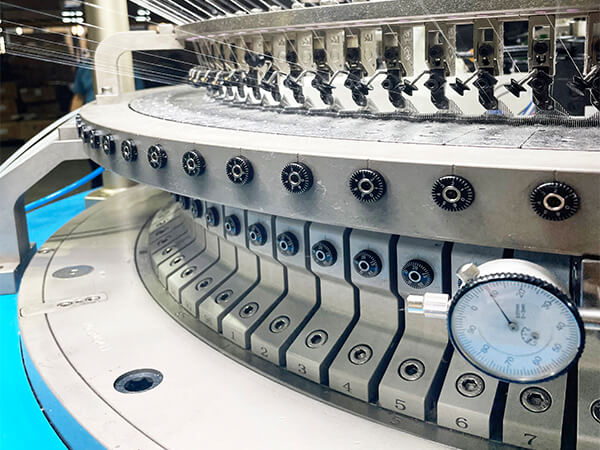

Scale marks are found around its circumference which maintains distance between fabric ends. This reliably ensures that the machine operates inch-by-inch and maintains accuracy.

The unique design of CSA (Central Stitch Adjustment) makes adjustment of fabric density to be easy and accurate.

Enhanced gearing system enables ease of operation, adjustment and smooth performance in a professional fabric knitting level.

Lycra is evenly and stably processed with the open width type knitting machine. Fabric winding is completed free of folds.

In producing chambray and quadrille a specific distance is maintained between the grilles of the cloth and its end ensuring uniform fabric structure.

You can specify different fabric usage be it Calico Weave, Cockled, Twill, Diamond Pique or Pique Mesh. With the specialized yarn feeder, the Open Width Knitting Machine can easily process many synthetic fibers to make a lot of plating fabrics, double thread velvet, urethane elastic fabric and elastic silk cotton.

Model | Cylinder Diameter | Machine Gauges | No.of Feeders | Speed |

ST-SJOW | 23’’-48’’ | 12-50G | 3 F OR 3.2F/Inch | 25 RPM |

Application Area: Swimwear, tights, underwear, T-shirt, polo shirt, gym suit, sportswear, technical textiles

| Equipment | STANDARD | OPTION A | OPTION B |

|---|---|---|---|

| Needle | Groz Beckert, Germany | Samsung, Korea | Yantex, Korea |

| Sinker (For single knit) | Kern Libbers, Germany | Samsung, Korea | Yantex, Korea |

| High Rigidity Special Design Robust Frame | SINTELLI | / | / |

| Zirconia Yarn Guide | SINTELLI | / | / |

| Yarn Feeder | SUN Feeder (B19) | SUN Feeder (B23K) | Global OR Memminger |

| Automatic oil Lubricator | Shengsong, Taiwan | Taiguan, Taiwan | Can be customized |

| Tube Creel | Triangle Creel | Creel with tube | / |

| 4 PCS Teeth Belt | MEGADYNE | / | / |

| Micro-computer control panel (3-shift counter and 4 digital RPM counter) | SINTELLI | Can be customized | / |

| Air System | Taiguan, Taiwan | Shengsong, Taiwan | Taishan |

| Inverter | TOSHIBA, Japan | Delta, Taiwan | Yolico, Japan |

| Motor | Teco, Taiwan | Sintelli | Delta, Taiwan |

| Take Down System | Fabric open take-down system | Sintelli Folding & Rolling take-down system | / |

| Cylinder | SINTELLI Japanese High Precision Alloy Steel material | / | / |

| Machine CAM setting | Single Jersey: 4 tracks Double Jersey: Dial 2 tracks, cylinder 4 tracks | Exchange cam parts for structions | / |

| Lycra feeder | SUN WAL5-4A/B | SUN WAL2-4A/B | Memminger |